Vacuum conveyor for food powders Spice vacuum conveying

Basic Info

Model No.: CWVC-

Product Description

Vacuum Conveyor Working Principle

when compressed air enter into the vanuum pump, simultaneously under the push of air cylinder, the empty door of hopper will be closed and the vacuum will be formed in the hopper. The cacuum feeding machine forms air stream under vacuum state. Under the action of this air steam the material which is conveyed will be transported to vacuum hopper through hose. Certain time later (feeding time, adjustable), the compressed air is closed, the pneumatic Vacuum Pump is unable to produce vacuum, simultaneously under the push of air cylinder the emptying door of hopper will be opened and the cacuum will be disappeared in the vacuum feeder. The material will be fed into receiving equipment from the emptying door (for example tablet press, packing machine and so on), simultaneously, compressed air that stores up in air packet's blowbacks the filter, and the filter cleans by itself. Certain time late (discharging time, adjustable), the compressed air starts again. Move in cycles, the material is fed into the equipment continuously.

Why Choose Vacuum Conveyor

For the vacuum conveyor with material level controller, automatic feeding of material in the hopper of the material receiving equipment can be realized through material level controller. When the material level is higher than ceitain position in the hopper of the material receiving equipment, the vacuum conveyor stops feeding, when the material level is lower than certain position in the hopper, vacuum feeder starts feeding automatically. And feeding for the material receiving equipment is completed.

Vacuum conveyor Characteristic:

---Using compressed air as primary energy sources

---Solving the stratification of powder and granules

---The filters made of Ti will never be jammed and be abraded

---Eliminate the static electricity

---Made of nontoxic and corrosion resistant materials

---Leakage free capsule, to prevent cross contamination

---Intelligent control and high automation

---Materials are not adhering to the inner surface of the conveyor

---Modular structure, easy to clean and dismantle

---Small and light ,easy to install

---Low noise and free from vibration

---Energy saving and low running cost.

Electrical Vacuum Conveyor Technical Parameter

| Type | Motor Power(kW) | Pump Type | Capacity(kg/h) | Pressure(mPa) | Size A*B(mm) | Feed Tube Diameter (mm) |

| CW-1 | 1.5 | Whirlpool | 400 | 0.6 | Φ220*820 | Φ38 |

| CW-2 | 2.2 | Whirlpool | 600 | 0.6 | Φ220*820 | Φ38 |

| CW-3 | 3.0 | Whirlpool | 1200 | 0.6 | Φ290*950 | Φ51 |

| CW-4 | 5.5 | Whirlpool | 2000 | 0.6 | Φ420*1250 | Φ51 |

| CW-5 | 4.0 | Roots Fan | 3000 | 0.6 | Φ420*1350 | Φ51 |

| CW-6 | 5.5 | Roots Fan | 4000 | 0.6 | Φ420*1450 | Φ63 |

| CW-7 | 7.5 | Roots Fan | 6000 | 0.6 | Φ420*1650 | Φ76 |

| CW-10-6 | 7.5 | Roots Fan | 6000 | 0.6 | Φ600*1500 | Φ76 |

| CW-20-5 | 11.0 | Roots Fan | 5000 | 0.6 | Φ800*1900 | Φ76 |

Note:

1-The Capacity based on Wheat Flour as raw material with 4 meters horizontal distance.

2-Conveying distance , conveying height and density are key points to decide capacity.

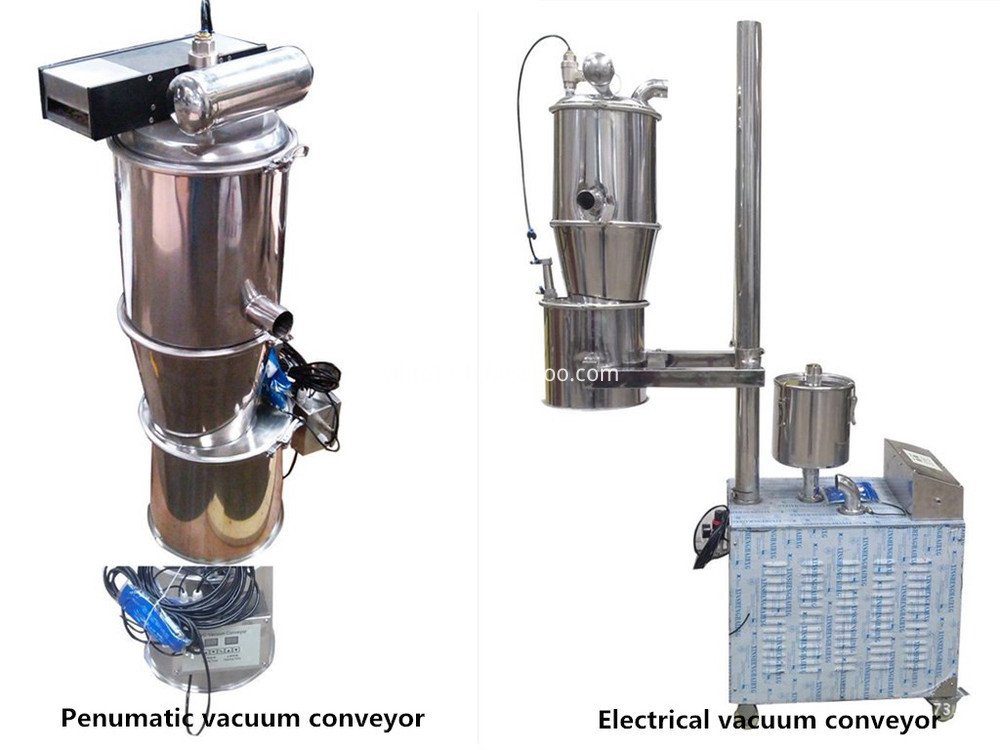

Pneumatic Vacuum Conveyor picture

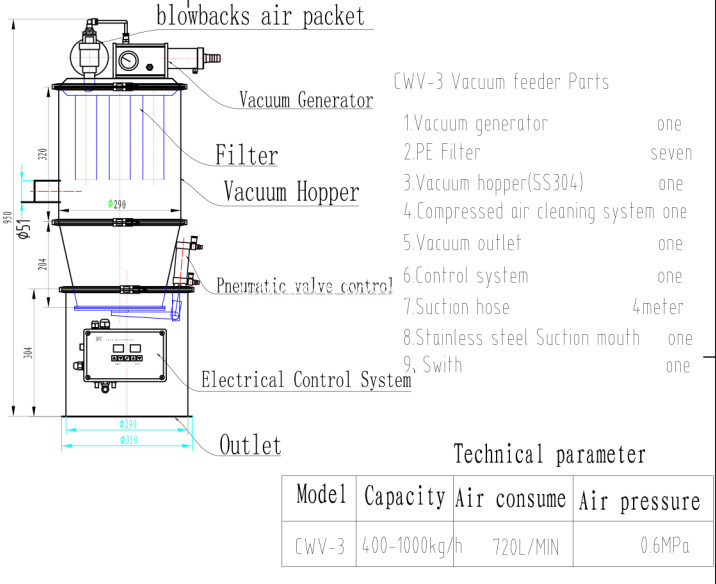

Pneumatic Vacuum Conveyor Drawing

Pneumatic Vacuum Conveyor Technical parameter

| Type | Silo capacity | Capacity(kg/h) | Pressure(mPa) | Air Consumption | Feed Tube Diameter (mm) |

| CW-1 | 3.5L | 350 | 0.4-0.6 | 180 L/min | Φ38 |

| CW-2 | 6L | 700 | 0.4-0.6 | 360 L/min | Φ38 |

| CW-3 | 12L | 1500 | 0.4-0.6 | 720 L/min | Φ51 |

| CW-4 | 42L | 3000 | 0.4-0.6 | 1440 L/min | Φ51 |

| CW-5 | 58L | 6000 | 0.6 | 2880 L/min | Φ51 |

| CW-6 | 96L | 9000 | 0.6 | 4320 L/min | Φ63 |

Note:

1-The Capacity based on Wheat Flour as raw material with 4 meters horizontal distance.

2-Conveying distance , conveying height and density are key points to decide capacity.

Piccture of Feeding packaging machine:

Piccture of Feeding Pulverizor:

Piccture of Multi-Connections:

Guarrantee and after sale service :

One year guarantee for the whole machine

24hours technical support by email

24 hours online service

Instruction in English language

User manual in PDF and Printed copy

Installation videos

Six free services including regular follow up services:

1.FREE technical enquiries

2.FREE repairs during warranty

3.FREE special services for key projects

4.FREE inspection upon delivery

5.FREE operation and repair training

6.FREE period follow-up and maintenance service

Our company

Chenwei Machinery has a professional production team, complete equipment, strong technical force. Mainly produces vibrating screen, air flow screen, solid liquid separator,polishing machine,screw conveyor,vacuum conveyor ,etc. Various materials and equipment, widely used in food, chemical, resin, pharmaceutical, ceramics, metal powder mining and metallurgy, paper and Other industries.

Product Categories : Conveying Machine > Vacuum Conveyor